Table of Contents

Have you ever thought that humans are the only creature on earth who wear an additional layer of fabric? Our Second skin is our clothes. They are on us since our birth and will be till our last breath. It defines our background, culture, personality, and a lot more.

Rightly said by Kofi Annan “Knowledge is power. Information is liberating.” – A Diplomat who served as the seventh Secretary-General of the United Nations (UN) from 1997 to 2006.

Inspired by the words of Kofi Annan, I am trying to spread powerful knowledge on Types of Fabrics with Name. And what could be the other uses of it?

I am Mohammed Ibrahim Anwar, and I am enjoying my ride as lead driver for my organization named A. K. Ismail. I am in the Textile and Apparel Industry since 1997 and my organization has been since 1947. Where I am the 3rd generation who is still building success stories.

Richard P. Feynman, a Nobel prize awardee in 1965 for “fundamental work in quantum electrodynamics”. He had said, “Nature uses only the longest threads to weave her patterns so that each small piece of her fabric reveals the organization of the entire tapestry.”

With all my years of expertise would like to take you on a journey where I will be explaining in detail of Types of Fabrics with Name. Let’s start with the basics….

What are Fabrics?

A series of yarn or thread when structured together in a systematic way gives birth to fabrics. The composition of this yarn or thread determines the feel and finish of the product. Based on this composition the fabric is categorized broadly as Silk, Wool, Cotton, Polyester, Etc. There could be a mix of categories named as Poly Wool, Poly Cot, Silk Cotton Etc.

How are Fabrics made?

In this section, we will have two broad categories. One would be Woven Fabrics and the other would be Knitted fabrics. As said earlier when the yarn is structured systematically, we produce fabrics. Below are the two main ways in which fabric is produced.

What is Woven Fabrics and how are they made?

Woven Fabric is two sets of yarn that run in two different directions and are interlocked in a systematic manner. The yarn that runs vertically is called Warp yarn and the yarn that runs horizontally is called weft yarn.

Considering the required density and the width of the fabric the yarn is placed in the Warp section. This yarn is rolled and is called a warp beam.

For the Weft yarn that runs horizontally through the width is a shuttle that carries the yarn and goes left and right in a systematic manner as to how many warp yarns it has to go on top and how many warp yarns it has to go below. Here again, the density is taken into account, and accordingly, the spacing is managed.

These woven fabrics are made on looms which are in 3 categories. a) Hand Loom. b) Power loom. c) Auto Loom. Having the above information, the industry plays around with various combinations like the yarn in the warp is of different quality, and the yarn in the weft is of a different quality. There are plain weaves and different types of weaves. Based on these various combinations, types of fabrics with name are derived.

What are Knit Fabrics how are they made?

Knitting is the construction of yarns by means of needles. It is aptly defined as the “Inter Meshing of yarn into loops to form Fabrics.”

In Knitting there are basically 2 systems to produce fabric, the first system being Weft and the other being Warp. Technically there is only one set of yarn that produces a loop with the help of needles that churns out fabric. Either it’s the Warp set of yarn or the Weft set of yarn.

Whereas in woven fabrics, looms have a warp beam of yarn that runs vertically. And a shuttle that carries the weft yarn runs horizontally left and right. A combination of the two produces fabric.

Weft Knitting

Using loops created horizontally by nearby needles, weft knitting is carried out. Circular knitting machines are the weft machines that are utilised the most. In a circular motion, this machine produces a cloth tube. Knits that are flatbed are created by the second kind of machine. On flat needle beds, these machines create cloth. Because of this, the result’s structure is not tubed.

In Short, Weft Knitting is when a set of yarn runs across the width and produces loops to create fabric it’s called Weft Knitting.

Warp Knitting

In Contrast to Weft knitting Warp Knitting is a set of yarn that forms loops vertically to produce fabric. Just as woven fabric there are warp beams, in which yarn is placed vertically. In this process, the yarn meshes vertically between two whales with help of needles. To understand this more clearly each yarn needs a needle. If we have 1000 needles, we need to have a minimum of 1000 warp yarns, if we have more warp yarns then the more elaborate the outcome of the fabric would be.

Types of Fabrics with Name – Basic Info

This textile industry is vast. Innovation and technology are at their best. Products are tailor-made to suit the needs and demands of the customer. The industry plays around with various yarn qualities.

Be it going solo in the composition of yarn or mixing two or three compositions of yarn. To suit the needs of the industry these yarns are fed on Weaving Looms or Knitted machines to produce fabric. I will try to give a bird’s view of what the industry produces and what they have named each of them.

Before we get any further, I would like to give you a small brief on “what is meant by yarn?” and “what is count in yarn”

What is Meant by Yarn?

Yarn is a collection of fibres that have been stretched or bonded together to create continuous strands. These fibres might be made of polyester, silk, cotton, or wool. Depending on the demands of the market, they may also be a blend of two or more fibres. Such strands’ weight and thickness are defined as counts in yarn.

What is Count in Yarn?

We all measure things by unit. Like weight in KG, Length in Cm or Meter Likewise the yarn is measured by the count. When the count increases the finer the yarn becomes. And when the count decreases coarse yarn becomes. For Example, 20’s yarn would be coarse than 60’s yarn. The coarser the yarn the weight increases. Hence 20’s yarn would be heaver compared to 60’s yarn.

Now let’s get to the mainstream Types of Fabrics with Name. Here we will have two headings one which is made on Looms which we will call woven fabrics and one which is done on Knitted machines, which we shall call knitted fabrics. Under these, we will list Types of fabrics with name.

Types of Fabrics with name – Woven.

Natural Fabrics

In the first place, what is the natural fabric? Fabrics which are direct from the loom, without any kind of process done are called natural fabrics. They are also called Grey Fabrics. Be it cotton, wool, silk or Polyester. But usually, the trend is most of the fabric is processed either dyed or printed and then given its end shape.

Another way to define Natural Fabrics would be any fabric derived from the fibres from nature vis Cotton, Flax, Jute, Silk Ect. Could be named Natural Fabrics.

Dyed Fabrics

After the fabric is made on looms it’s boiled and processed in various chemicals to give it colour. These are called Dyed Fabrics.

Yarn-Dyed Fabrics.

In this category, the yarn is dyed in various colours and then put on warp beams, and another set of yarns is fed in shuttles of the weft. These put together creates yarn-dyed fabric. If a single colour is fed in both the warp and weft, we have a plain fabric. If a combination of colours is used in a systematic manner the looms produce great designs.

Printed Fabrics.

As the name says the fabric is printed. But before the print is done the fabric is processed in chemicals so that the greasing that goes on the looms for the production of fabric is removed. And after which it is printed.

Jacquard Fabric / Doby weave fabric.

Jacquard Fabric is a design done while weaving. Like a flower design or a self-stripe design etc. The concept is that the design is done at the looming stage.

Rayon Fabric.

Rayon is a natural fibre mixed with certain chemicals to give that silky look. This gives great comfort as cotton and is not as strong as cotton. We could say this is semi-synthetic. Generally used in summer. This is an easy-to-maintain fabric.

Modal Fabric.

It is designed to be extremely silky. Lenzing modal is harvested from seashore trees and is a second-generation cellulose-tic fibre that resembles rayon.

Linen Fabric.

Linen is a natural fibre produced from Flax Plant. Just like cotton is a natural fibre grown on the cotton plant. It’s extremely breathable and gives great comfort in wearing.

Viscose Fabric.

Viscose is a natural fibre manufactured by humans. It is made of a combination of cotton and wood pulp, which is then chemically bonded. And a viscose fibre is incorporated. The increased moisture absorption of a 100% viscose fabric makes it suitable for usage in the summer.

Synthetic Fabrics.

Synthetic fabrics are made from petroleum by-products. They are strong and easy to maintain. Preferable to be worn in winter to give a warm feel.

Terry Weave Fabric. / Towelling Fabric.

This fabric contains loops on both of its faces. Three sets of yarn are in play in this fabric. As usual, the ground cloth is made of warp and weft. The loops are created with the third set of yarn that passes through the ground layer. Terry is the term for these loops. The major use of these fabrics goes to manufacture towels, the selvedges of this cloth are cut and stitched together to give the shape of bath linen. Find out more about towels by visiting the Bath Towels blog.

Waffle Weave

This fabric’s face resembles a square waffle exactly. Typically, it is made of coarse yarn and natural fibers. Primarily used for bath towels. Thus, using natural fibers provides excellent absorbency, and waffle texture facilitates the process of absorption

Canvases

This is extremely tightly woven and made of coarse yarn. used across industries for a wide range of functions, even while in its natural form. Bags versions of Canvases can that have been dyed and printed. made from cotton, or a combination of cotton and polyester, or 100% polyester yarn. Whereas other Industries use it for their machine components. Another famous attire for canvases can be Industrial aprons while welding. The list can go on….

Tie and Dye Fabric

This is a fantastic piece of amazing human art. where different points on fabric are tied before being coloured. The magic happens when the chemicals or dyes dry and the knot is undone, revealing a beautiful circular pattern. The unique aspect is that no two pieces will be identical. Because it is handmade, it is impossible to attain design uniformity. Typically, it is made on apparel rather than fabrics.

Laminated Fabrics

A coating is applied on fabrics for a specific reason, regardless of its properties. in order to address a certain issue. To create the effect of a sticker, for instance, an adhesive coating is applied to the cloth and paper is affixed. So that when the fabric is affixed the paper has to be removed and the fabric affixed.

Another illustration is the stiff collar on a man’s shirt. Can you picture how could this be so stiff? Inspite of so many washes? The procedure involves placing a small amount of minute grains or a chemical coating on the base of stiff fabric. The desired collar shape is then cut out of this fabric, and it is rolled firmly over a hot iron box to permanently bond it.

So Laminated fabrics are those that have an extra layer to solve a specific purpose.

Batik Fabrics.

Wax is placed on the fabric in specified locations to form a design, during the batik process, it’s a sort of resist printing. The fabric is dipped in dye as the wax solidifies. As a result, the dye cannot reach the fibres. To remove the wax, the fabric is subsequently boiled. The fabric seems cracked when dying in this way. This has a patternless appearance. This process and look define the features of Batik.

Handloom Fabrics.

As we are speaking of woven fabric and as explained earlier, we have a warp yarn running vertically and a horizontal yarn running called the weft. As the warp side is stationary and the weft yarn is running in between the warp yarn hence producing fabric. The whole process when done with human efforts and without electricity or any other power is called handloom.

Power Loom Fabrics.

The process as explained in handloom fabric when done with help of electricity or other external power is called power loom fabric. A power loom gives increased production and better quality of fabric compared to a handloom.

Auto Loom Fabric.

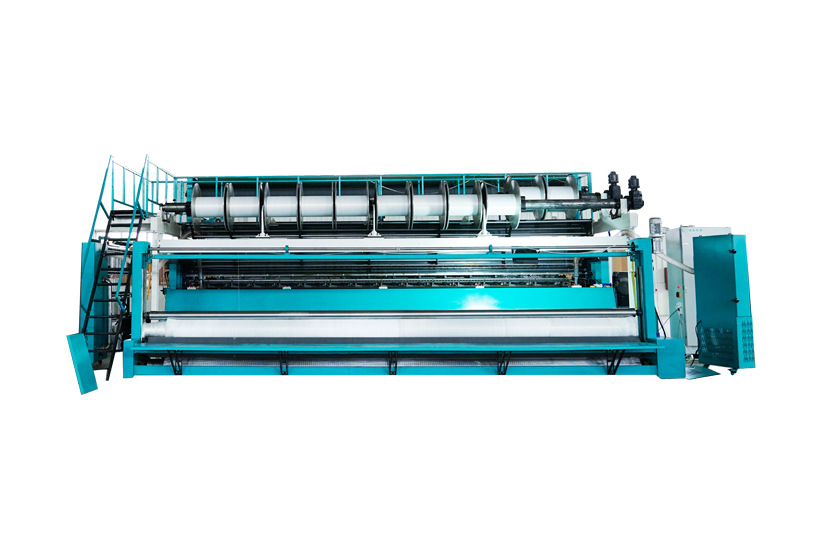

Since technology is a driving force in this sector of the economy, auto looms were introduced to eliminate fabric production faults and boost output. As technology advanced, it is important to keep in mind that only superior-quality raw materials can ensure that machinery operates without interruption.

Even just one strand of yarn breaks, auto looms will halt output until the operator fixes the problem and then resumes the operation. As a result, the fabric’s final product is flawless.

In contrast to power looms and handlooms, the operator must exercise caution to ensure that no yarn strands break and that there are no weaving flaws.

Plain Weave Fabric.

This category of fabric looks plain on its face of it. As the weave is generally one warp yarn runs over one weft yarn hence has a plain effect.

Twill Weave Fabric

Twill weave is a robust fabric. To identify the face or the right side you may see a series of cross lines running from one width to another. Another check is that the lines would start from the left to the right. The back side would be like a matrix and would not have a line or rib effect.

Herringbone Fabric.

It’s very similar to twill fabric and is alternatively called broken twill. The face of it would look like a V shape. Unlike the twill weave, the rib lines would continue all through but in this weave, the rib lines would have a V effect hence it’s named broken twill.

Satin Weave Fabric.

A cloth with a satin weave has a lovely drape and is glossy and silky. One side of the satin cloth has a silky, shiny surface, whereas the other side has a duller surface.

Voile Fabric.

Voile is a thin, nearly transparent fabric. Produced from either 100% cotton or 100% polyester. The yarn used in voile fabric is very fine and lightweight, secondly, it is loosely woven so that it gives an almost transparent feel. Also available in a cotton and polyester combination. Depending on the need, the fabric finish is either crisp or soft. Typically used for women’s clothing and curtain drapes.

Narrow Woven Fabrics.

Narrow woven fabric is any woven fabric with a width of 12 inches or less. A narrow-woven fabric could be lace, tape, rope, etc. They are made on a much smaller width of looms and usually on the power loom sector. As the width and value of the product are small the MOQ is large and has a huge production.

Seersucker Fabric.

A fabric which is light and usually made in 100% Cotton. The look and feel of this unique fabric are that it has a puckered effect and it’s natural and would not lose this puckered effect till the life of the fabric. The science and ideology of this fabric are like this. When the fabric is woven on the looms the output would be a plain fabric. The magic of this puckering effect happens when it goes through the process of either dying or washing.

When the fabric is woven, it’s woven having different qualities from yarn. As each yarn behaves differently during fabric processing and washing. One yarn would shrink with a different percentage and the other yarn would not shrink or shrink with a different percentage. Hence that puckering effect. And still, this placement of different qualities of yarn evolves a great pattern.

Types of Fabric with name – Knits.

Just like woven the fabric are categorized by their bled composition and their weaves. I would like to list the common Types of fabric with name which are mentioned in woven and are also applicable in knits so that I do not have to repeat the same.

1. Natural Fabrics.

2. Dyed Fabrics.

3. Yarn Syed Fabrics.

4. Printed Fabrics.

5. Modal Fabrics.

6. Viscose Fabrics.

7. Synthetic Fabrics.

8. Terry / Towelling Fabric.

9. Waffle Weave Fabric

10. Tie and Dye Fabric.

11. Laminated Fabrics

Apart from the above Types of fabrics with names in knits, we will list some more which are unique to the knit industry.

Jersey

Fabrics classified as flat or jersey knit include prominent horizontal ribs on the back and obvious flat vertical lines on the front. The flat or jersey knit stitch is often used because it is quick, inexpensive, and can be altered to generate fancy patterned fabrics.

Rib Knit

Rows of wales are created on both the front and back of rib stitch knits because the stitches are drawn to both sides of the fabric. Excellent flexibility is a characteristic of rib-stitch materials. Rib knits are utilised for the “ribbing” that is typically seen around necklines, sleeve cuffs, and lower margins of sweaters.

Interlock Knit.

Rib knits come in a variety of stitches, including interlock. Interlocks have the same front and back. Except when using finer yarns, these textiles are often heavier and thicker than standard rib knit fabrics. The overlapping of the stitches stops runs and results in clothing fabrics that do not curl or ravel at the edges.

Pique / Airtex

These types of fabric with the name Pique or Airtex are made in cotton, a blend of cotton or 100% polyester. They have minute holes or a kind of matt finish which are visible on the face side of the fabric. The back has a regular knit weave. These holes or the mat kind of finish keep the fabric breathable.

Lycra Rib.

As previously indicated in Types of fabrics with name. Rib-knit is just a small amount of lycra added to the same knit structure to give the fabric that extra elasticity. commonly seen in socks and other similar products, where the most flexibility is needed.

Auto Stripes.

It’s a yarn-dyed product where horizontal lines are designed. Generally knitted in Pique, Jersey, or Rib. Can have various combinations of 100% cotton or 100% Polyester or a blend of both. As required by the market.

Loop knit

A knit structure in essence, where the knit on the reverse side of the fabric gradually produces a loop effect with the aid of machine needles. This fabric’s GSM is relatively high, making it suitable for bottom clothing or winter apparel.

Loop knit Brushed

Let’s explain the word “brushed” in the fabric sense. A process in which the yarn is typically teased in a way that fibres are elongated, which in turn gives a soft fluffy feel. It’s to be noted that yarn would be teased either on the face side or the reverse side. Whichever side it’s teased only that side would be soft.

So loop knit brushed is that fabric which is teased on the loop side to give a soft feel. Whereas the top side is not disturbed. The yarn loop’s back side has more yarn face than the front, hence brushed effect or the fluffy effect has a superior smooth texture.

Frequently Asked Questions.

Give one example of value addition in the Textile Industry.

Textile Industry Is technology driven and new products are introduced as per the demands of consumers. VALUE ADDITION can be equated saying “surgically solving a problem of market requirement.” Let me give you a couple of examples.

1. Wrinkle-free Cotton.

2. UV Protection

3. Anti-Microbial

Where is cotton textile industry in India?

The cotton Textile Industry can be divided into 2 categories. The first is the cotton-producing crops. Then comes the spinning, weaving, and processing sector.

The Indian states of Maharashtra, Gujarat, Andhra Pradesh, and Telangana, collectively referred to as the Cotton Basket of India, produce over two-thirds of the country’s cotton-producing crops.

The second category of the cotton textile industry is spread out in Maharashtra, Gujarat, and Tamil Nadu. Numerous organised sectors and unorganised sectors have a role to play.

Cotton Textile Industry in Tamil Nadu in shorts.

· Tamil Nadu is the leading producer of cotton yarn and the leader in the export of cotton yarn.

· Has the maximum number of handloom clusters.

· An organised and super eco system which consumes the abundant supply of cotton yarn in power loom and handloom clusters.

· Dedicated Technical Textiles Parks have been situated in Karur & Kanchipuram.

· Tirupur is Asia’s largest knit producer.

· Erode houses a large number of Power loom weavers, Dying, Processing, and finishing units.

· India’s 50% Of garment units are based out of Tamil Nadu.

Famous Cotton Textile Industry in India.

Cotton Textile Industry in India stands on 4 pillars. Which are 1) Raw Cotton 2) Yarn 3) Fabrics 4) Made-up and Apparel.

As per data collected from TEXPROCIL and AEPC. The following are the export value done throughout the world for the year ending March 2022. (All figures in Million USD)

1. Made-ups and Apparel accounts for USD 6284.35

2. Yarn accounts for USD 5518.93

3. Fabric accounts for USD 3101.70

4. Raw Cotton accounts for USD 2816.44.

We could rightly say that India is famous for the made-up and apparel industry. Where India is well known for agriculture and skilled labour. Hence India has a great edge over other countries.

One centre of Cotton Textile Industry with Name.

Coimbatore is Known as the ‘Manchester of South India.’ Coimbatore produces Cotton yarn which is supplied across India and widely exported.

The Fibres present in Cotton Fabrics are of?

Natural cotton is a material that comes from cotton plants. It is made up of several fibres with various lengths. Cellulose, an organic compound that cannot be dissolved and is crucial to the structure of plants, makes up the majority of the soft, fluffy material that is cotton.

What are Cotton Fabrics used for?

Cotton is known for its Softness, Durability, Absorbency, and breathability. Due to this, they are used for the following.

Ø Apparel.

Ø Bed and bath linen.

Ø Under Garments.

Ø Home Décor.

Ø Industrial and technical textiles.

Ø Tents.

What are the Properties of Cotton Fabrics?

Cotton fabrics contain 94% cellulose, which is a hollow fibre. The following are the well-known properties of cotton fabrics.

1. They are breathable. Excellent wicking process. Top of all, they are soft and cool.

2. Withstand abrasion to high temperature. A good product for industrial use.

3. They are dye absorbent. A staple material for the fashion industry.

4. They wrinkle easily. Hence need to maintain.

5. Cotton Fabrics can hold up to 25 times their weight. They are stronger when they are wet. And that is why greatly used in bath linen and kitchen linen.

6. Being a natural product they are nontoxic and biodegradable.

If you found the above article to be interesting and inspires you to put your ideas into action. I can help people evolve with great products that truly meet their expectations. Let me still inspire you by telling you that I can work out supper light MOQ so that you would feel comfortable in various aspects. As mentioned earlier I have been serving this industry for the past two and half decades and still counting. Do get in touch with me on my contact page and sure you will receive a reply from me.

Thanks,

Mohammed Ibrahim

+91 9677253786

Email : [email protected]

Pingback: A List Of Best Natural Fabrics Names & Qualities In Market

Pingback: What Is Muslin Cloth? Divine Secrets Of The Softest Fabric!

Pingback: Dressed For Glory: Unraveling The Secrets Of Army Combat Uniform - Weaversfruit.com